Survey

On October 31, 2018, an acceptance group was formed by the Minister of Investment and Development, the person in charge of equipment, the person in charge of electricity and the relevant departments of Liuhe Forging Co., Ltd. to check and accept the turbid water system supplied by Beijing Luheng Science and Technology Co., Ltd. The acceptance group inspected the operation of the turbid water system equipment and the effluent effect on the spot, and carefully reviewed the relevant technical data. Check the acceptance monitoring report, confirm that the effluent index meets the production needs of special steel rolling, agree that the equipment and performance test of the project meet the contract requirements, and pass the project with higher evaluation and acceptance.

Construction background

Sichuan Liuhe Forging Co., Ltd. is located in Jiangyou City, Sichuan Province, an important special steel base in China. Founded in April 2004, the company is a subsidiary of Mianyang Science and Technology City Investment Development (Group) Co., Ltd. of the State-owned Enterprises Commission. It specializes in manufacturing high-end and important equipment materials and components such as aviation, naval ships, nuclear power, gas engines and so on. The company is under the jurisdiction of Sichuan Liuhe Shanghai Branch, Beichuan Qiang Autonomous County Liuhe Steam Turbine Co., Ltd., Deyang Liuhe Energy Materials Co., Ltd., Germany Kaimande International Co., Ltd. and other wholly owned subsidiaries and subsidiaries.

In 2017, Sichuan Liuhe Forging Co., Ltd. built a new production line. According to the production scale and technology, the water quantity and water quality index of each equipment are required. At the same time, the turbidity water treatment system of this project is constructed according to the principles of low-carbon economy, water saving, reducing environmental pollution and improving the reuse rate of production water.

The scale of turbid water treatment in this project is 400 m/H, including all the construction contents of lifting pump house, sedimentation tank, mud treatment room, high efficiency turbid water purifier, cooling tower, charging system, electrical system, PLC automatic control system, pipeline and installation, supporting civil engineering, etc.

The turbid circulating water system mainly supplies turbid ring cooling water for heating furnaces, rolling mills, rolls and other equipment. Its characteristic is that it contacts directly with the products in the process of use, so that the backwater not only increases the water temperature, but also pollutes the water quality, so the backwater directly enters the slag flushing ditch of the rolling mill iron sheet. After the iron-containing wastewater is flowed into the sedimentation tank to remove large particles of iron oxide scale by precipitation, the pumps set in the sedimentation tank are used to pressurize and send to the high-efficiency turbid water purifier for enhanced flocculation and sedimentation to remove iron chips, suspended solids and oil in the water. After that, the residual pressure is directly flowed into the cooling tower for cooling and cooling, and pumped back to the production workshop for recycling.

In the bidding process of this project, the turbidity water treatment equipment and process in the form of short process and pressure of Lvheng Science and Technology have been approved by the owner with excellent cost performance ratio and signed a general contract for the project. Lvheng Science and Technology is responsible for the technical services related to the basic design of the project, the supply of the complete set of process equipment, the construction and installation, and the debugging of the equipment unit. Through the sincere cooperation with the owners, the company ensures the smooth completion and commissioning of the project construction in the shortest time.

Treatment effect

After treatment, the water quality is up to the standard

Built meaning

After completion, the water quality of the treatment reached the standard to meet the requirements of production and operation. At present, it has been running for three consecutive months, and running well, ensuring the safety and stability of the water requirements of the production line.

— Influent suspended solids:SS<300mg/L

— Effluent suspended solids:SS<30mg/L

— Intake water contains oil:<10mg/L

— The effluent contains oil:<5mg/L

Brief Introduction of Technology-High Efficiency Turbidity Water Purification System of Lvheng Science and Technology

Core Equipment and Process Flow

Beijing Keheng Technology Co., Ltd. relies on more than 20 years of practical engineering experience in water treatment in iron and steel and metallurgical industries, and develops ZHFM high-efficiency turbid water purifier, which is a turbid water treatment system composed of supporting equipment and patented technology (integrated non-power hydraulic circulating purifier, patent No. ZL 031 13421.1). It is the latest generation of high-efficiency, energy-saving and short process. The new turbid water treatment process can effectively remove oil and suspended substances in water, and the treated effluent can enter the cooling tower with pressure to cool. It is a new process with short flow, high integration, low energy consumption, less land occupation and low maintenance cost.

Since the product was successfully developed and put into production, it has been highly recognized and recommended by leading design units and equipment suppliers in metallurgical industry such as Beijing Cheng, Saidi, Sinopec and Danieli Group, and has cooperated with hundreds of large steel companies such as Baosteel, Baotou Steel, Pinggang, Tiangang, Ronggang, Lingyuan Steel and Lianfeng Iron and Steel to supply EPC equipment. To be widely recognized, with a large number of performance cases and a high market share.

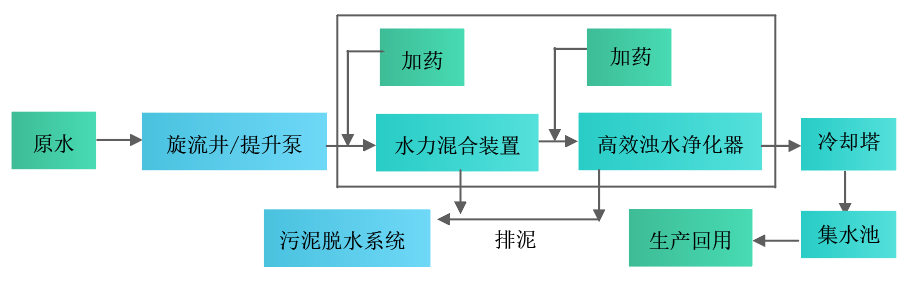

The process flow of high efficiency turbid water purification device is as follows:

Note: Inside the wireframe is the core part of the processing technology.

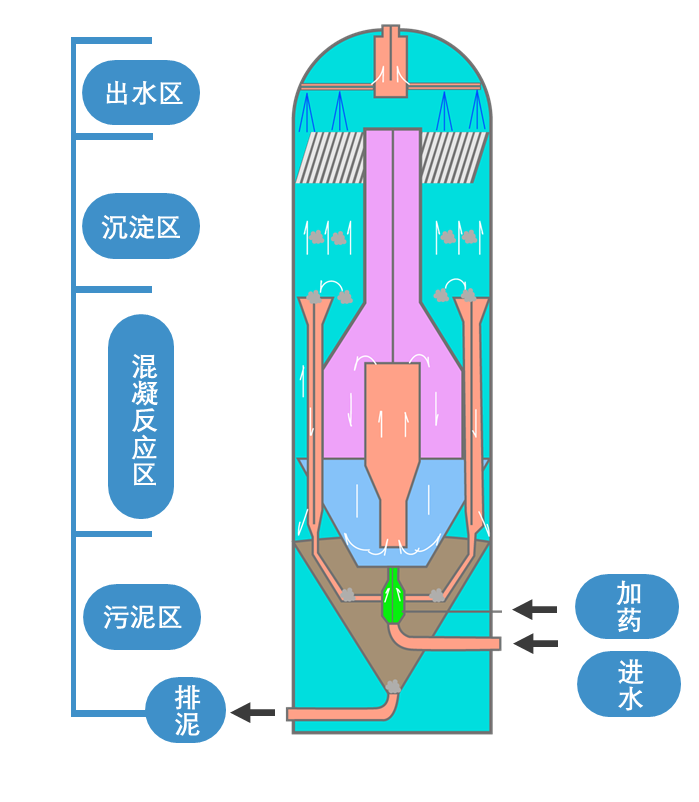

Structure and Principle

Turbidity circulating water passes through the hydraulic circulation, eddy current mixing and sludge reflux built in the purifier, and keeps the concentration of internal reflux sludge continuously. With the aid of coagulant, colloids and fine suspended matter in turbidity circulating water are destabilized and coagulated into flocculents. With the help of adsorption, electric neutralization, bridging and other functions, large granular flocs are gradually formed, which enter the bottom sludge collecting bucket where water is still and settles rapidly. The unsettled fine particles are further filtered and intercepted by the intermediate suspended sludge layer before entering the inclined pipe sedimentation zone. Under the action of the sedimentation inclined pipe, the remaining particles gradually coalesce and slide into the sedimentation chamber. The reflux system in the equipment is completely hydraulic, and there are no mechanical parts in the equipment.

Characteristics and Technical Advantages of High Efficiency Turbidity Water Purifier

(1)The innovative turbid water treatment process adopts the patented technology of Greenhouse Science and Technology and integrative pressure design. The process flow is short, the equipment integration is high, the automation is high, the treatment efficiency is high, and the effluent quality is stable.

(2)Equipment serialization complete supply, overall factory transportation and installation, site construction and installation of short duration.

(3)The hydraulic surface load of the purifier ranges from 20 to 40 m/ h, which occupies more than half of the total area of the purifier compared with the conventional treatment process, and the amount of civil engineering is small.

(4)Sludge reflux technology is used to improve the anti-impact load ability, mixing, reaction efficiency and contact time, give full play to the full efficacy of the agent, and the utilization rate of the agent is high. Equipment integration is high, power consumption is low, and the comprehensive operation cost of the system is low.

(5)The operation and maintenance of the equipment are simple, there are no mechanical transmission parts in the purifier, and the maintenance workload is low.

(6)The water content of slurry discharged from equipment is about 95%, which is low. Water resources are saved while the load of slurry treatment equipment is reduced and the operation period is shortened.